Support customization and sample delivery!

How to produce borosilicate glass

Author:

Munan Glass

Date:

2025-07-01

Read:

How to produce borosilicate glass is a detailed guide that covers the entire process of creating this unique type of glass. Borosilicate glass is known for its durability and resistance to thermal shock, making it an ideal material for laboratory glassware, kitchenware, and more. In this article, we will explore the materials needed, the steps involved in production, and tips for ensuring the best quality in your borosilicate glass.

To produce borosilicate glass, the primary ingredients include silica sand, boron trioxide, soda ash, alumina, and other additives. Each component plays an essential role in achieving the right properties in the final product. The silica sand provides the glassy structure, while the boron trioxide enhances thermal resistance. Soda ash lowers the melting point of the silica, making it easier to work with, and alumina contributes to the overall strength of the glass.

The first step in producing borosilicate glass is to carefully measure and mix these raw materials in precise quantities. A typical recipe might include around 70% silica, 10-20% boron trioxide, and smaller percentages of soda ash and alumina. After mixing the ingredients thoroughly, the next step is to melt the batch in a furnace at high temperatures, typically between 1400°C and 1600°C.

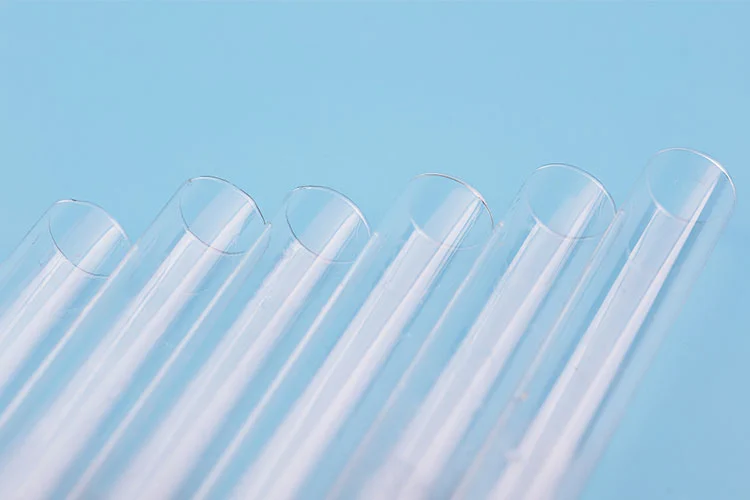

During the melting phase, it’s crucial to maintain the right temperature and atmosphere in the furnace. The ideal atmosphere prevents any unwanted reactions that could compromise the quality of the glass. Once the batch is fully melted and homogeneous, it can be formed into various shapes as required, such as tubes, rods, or custom-designed glassware.

Once formed, the glass needs to undergo a controlled cooling process called annealing. This process reduces internal stresses in the glass by slowly cooling it down, typically in an annealing lehr, ensuring that the glass maintains its integrity during use.

It’s essential to inspect the final product for any defects such as bubbles, cracks, or uneven thickness to ensure that it meets quality standards. Quality control is vital in borosilicate glass production, as imperfections can lead to failure in high-temperature applications.

Borosilicate glass production involves a complex process that requires specialized knowledge and equipment. Begin with high-quality raw materials including silica, boric oxide, and other essential components. These are carefully measured and mixed to ensure the correct chemical composition. The mixture is then heated to extremely high temperatures in a furnace until it melts into a homogeneous liquid. Once molten, the glass is shaped through various methods such as blowing, pressing, or drawing to create the desired form, like tubes or rods. After shaping, it undergoes a controlled cooling process known as annealing to relieve internal stresses and enhance durability.

When it comes to sourcing materials, there are numerous borosilicate glass tube suppliers in the market. These suppliers offer borosilicate glass tubes that come in standard tubing sizes, catering to different industrial and laboratory needs. The tubes are valued for their excellent thermal and chemical resistance properties, making them suitable for applications in chemistry, pharmaceuticals, and lighting industries, among others.

Similarly, borosilicate glass rod suppliers provide rods that are used in a variety of applications, from glassblowing to the manufacturing of scientific instruments. Borosilicate glass for sale, whether in tube or rod form, is widely available through various suppliers who can meet different specifications and requirements. When purchasing, it's important to consider factors such as the glass's coefficient of thermal expansion, optical properties, and overall quality to ensure it meets the specific needs of your project. With the right supplier and careful selection, borosilicate glass can be a versatile and reliable material for numerous applications.

In summary, producing borosilicate glass involves an intricate process that requires precision and care to achieve the desired quality. Understanding the importance of each ingredient, the melting process, and subsequent cooling methods are crucial for anyone interested in creating their own borosilicate glass products.

Related news

Related products

PRODUCT CATEGORY